Drilling with Mud

Enhancing Performance and Overcoming Challenges

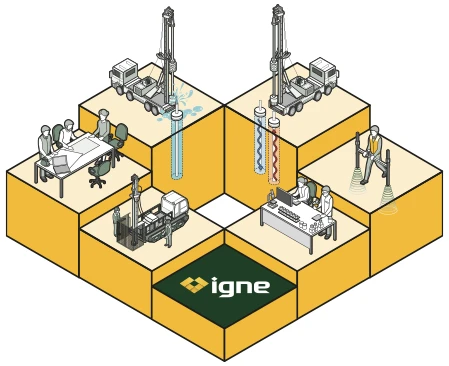

About

Drilling Fluid

Drilling with mud, also known as drilling fluid, is an essential technique in specialist land drilling.

Mud plays a crucial role in ensuring smooth operations, stabilising boreholes, and managing challenging geological conditions.

At Igne, we are experts in all forms of drilling, including the strategic use of drilling mud to improve efficiency and mitigate risks across diverse projects, from geothermal installations to ground investigations

The Reason

Why Drill with Mud?

Drilling fluid, commonly referred to as "mud," serves multiple purposes in the drilling process. It is a specially formulated mixture used to:

- Stabilise Boreholes by preventing collapse in loose or unstable formations

- Cool & Lubricate the drill bit, reducing wear and extending equipment lifespan

- Control Subsurface Pressures, particularly in formations prone to artesian conditions

- Carry Drill Cuttings to the surface, keeping the borehole clear and facilitating analysis

- Minimise Fluid Loss into surrounding formations, preserving the integrity of the drilled hole

Without the correct drilling mud, projects can face significant delays, equipment failures, and safety risks. Igne’s specialist teams have the expertise to select and apply the right mud formulations for any drilling scenario.

Explainer

What is Mud in Drilling Terms?

In drilling, "mud" refers to a liquid or semi-liquid drilling fluid used to optimise borehole stability and drilling efficiency. It is more than just a mix of water and earth, it is a carefully engineered solution designed to meet specific site requirements.

The composition of drilling mud varies depending on the geological conditions, depth of drilling, and project objectives.

The Process

Types of Drilling Mud & Their Uses

Drilling muds come in different formulations, each with unique properties suited to particular drilling conditions:

- Water-Based Mud (WBM)

A simple yet effective mixture of water and additives, used in many drilling applications for its ease of use and environmental benefits - Polymer Mud

Uses special polymers to enhance borehole stability and reduce water loss, ideal for drilling in unconsolidated formations - Bentonite Mud

A clay-based mud that swells in water, creating a strong filter cake to prevent fluid loss in porous formations

Each type of mud is carefully selected based on the geology and challenges of the specific drilling project. Igne’s drilling experts analyse site conditions to determine the optimal mud composition for safe and efficient drilling.

The Benefits

The Benefits of Drilling with Mud

The correct use of drilling mud provides multiple advantages:

- Enhanced Borehole Stability. Prevents collapse and minimises borehole wall erosion

- Improved Drilling Efficiency. Reduces friction and enhances penetration rates

- Better Cuttings Removal. Clears debris efficiently, keeping the borehole clean and functional

- Controlled Formation Pressures. Prevents uncontrolled water inflows, particularly in artesian conditions

- Reduced Environmental Impact. Properly managed drilling mud reduces fluid loss and contamination risks

With Igne’s expertise in drilling fluid selection and management, clients can be confident in achieving optimal drilling outcomes with minimal risks.

Eliminating Risk

Are There Any Issues with Using Mud in Drilling?

While drilling mud is essential, improper selection or management can lead to problems, including:

- Excessive mud weight causing formation damage or lost circulation

- Environmental concerns if drilling fluid is not disposed of correctly

- Clogging and filter cake build-up in certain formations, requiring additional treatment

To avoid these issues, Igne ensures precise formulation, monitoring, and disposal of drilling mud in compliance with industry regulations and environmental best practices

FAQ

Frequently Asked Questions About Drilling with Mud

- What is drilling mud made of?

Drilling mud is typically composed of water, oil, or synthetic fluids mixed with clays, polymers, and chemical additives to achieve the desired properties.

- Why is drilling mud important?

Drilling mud provides borehole stability, lubrication, cooling, and pressure control, making it essential for safe and efficient drilling.

- What happens if the wrong mud is used?

Using the wrong mud can lead to borehole collapse, fluid loss, drilling delays, and even environmental contamination. Expert selection and monitoring are critical.

- Can drilling mud be reused?

Yes, drilling mud can often be treated and reused, reducing costs and minimising waste. Proper management is essential for maintaining effectiveness.

- Is drilling mud environmentally friendly?

Some types, such as water-based and synthetic-based muds, are designed for minimal environmental impact. However, proper disposal and treatment are necessary to prevent contamination.

The Next Step

Bring in the Experts

If your project requires drilling with mud, you need a team that understands the science behind the selection and management of drilling fluids. Igne has the expertise to optimise drilling efficiency, prevent costly mistakes, and manage environmental considerations.

Whether you’re planning a new borehole or need help overcoming drilling challenges, get in touch with Igne today.

Our specialist drilling teams are ready to provide the expert support your project needs.

Artesian Boreholes

Angle Boreholes

Drilling with Mud

Large Diameter Boreholes

Deep Boreholes

Acidisation

Hydrofracturing

Dewatering

Monitoring Boreholes

Vibrating Wire Piezos

Fibre Optics

Seismic Monitoring

Deep Wireline Coring

Gas Control

Deep Soakaways

Decommissioning

Specialist Plant & In Hole Equipment Hire